Sheet Metal Bending Exercises Pdf . Statement of the basic laws governing deformation in sheet metal and the application of large modelling packages. You’ll use a combination of different flange features to create the base and utilize. Insert bends or “convert to sheet metal” features. Click on the sheet metal tab in the ribbon. Cutting and forming thin sheets of metal usually performed as cold working. Sheet bending is defined as the straining of the metal around a straight axis. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. When designing with sheet metal, it is important to think about the best approach to model or. In this exercise, you’ll create a sheet metal bracket. Open a new sheet metal part workspace from alibre design's home. During bending operation, the metal on the inner side of the.

from inchbyinch.de

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Insert bends or “convert to sheet metal” features. Statement of the basic laws governing deformation in sheet metal and the application of large modelling packages. Open a new sheet metal part workspace from alibre design's home. When designing with sheet metal, it is important to think about the best approach to model or. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Cutting and forming thin sheets of metal usually performed as cold working. Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the. Click on the sheet metal tab in the ribbon.

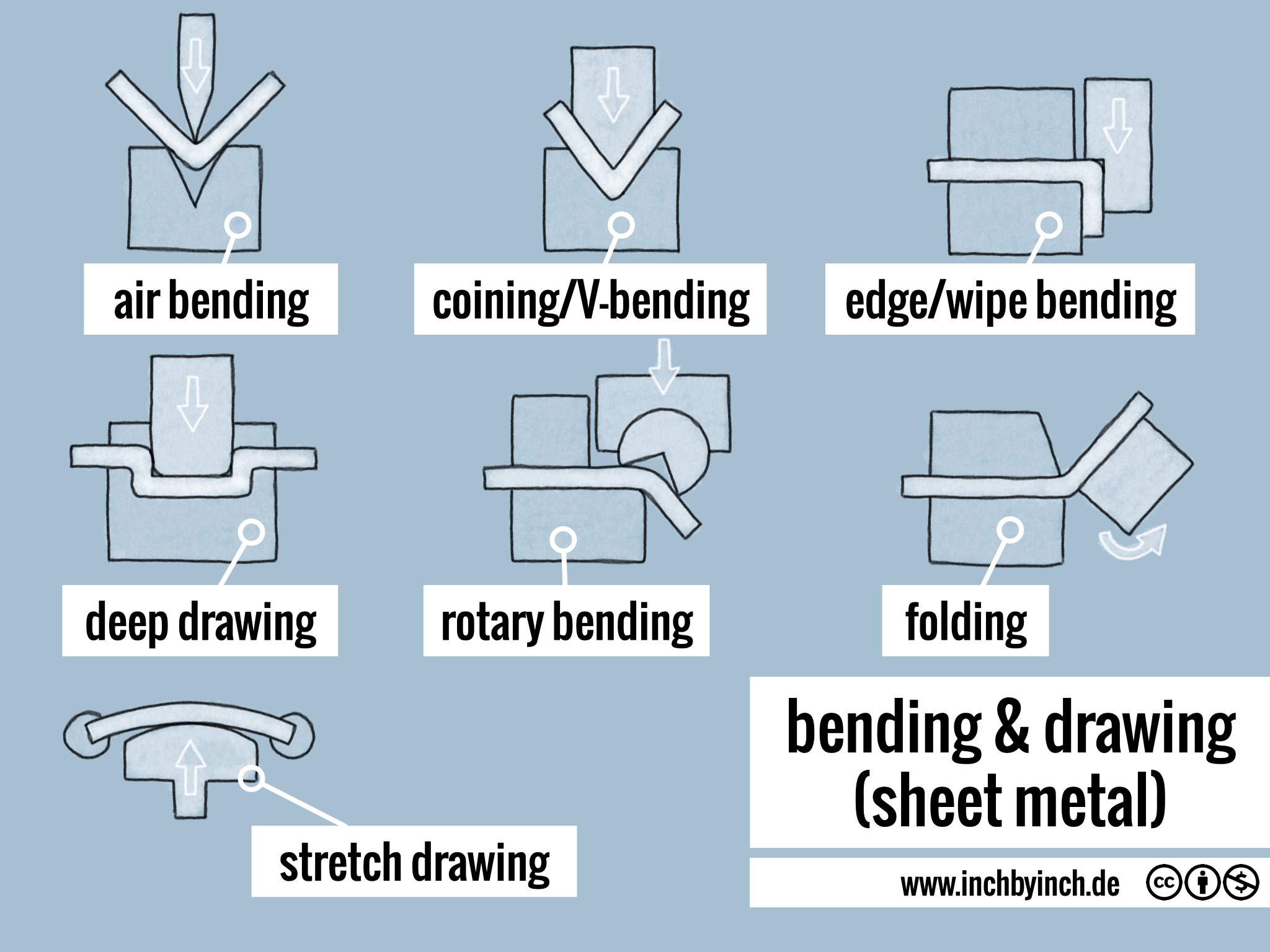

INCH Technical English pictorial bending & drawing (sheet metal)

Sheet Metal Bending Exercises Pdf You’ll use a combination of different flange features to create the base and utilize. Click on the sheet metal tab in the ribbon. During bending operation, the metal on the inner side of the. Open a new sheet metal part workspace from alibre design's home. Cutting and forming thin sheets of metal usually performed as cold working. You’ll use a combination of different flange features to create the base and utilize. When designing with sheet metal, it is important to think about the best approach to model or. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Insert bends or “convert to sheet metal” features. In this exercise, you’ll create a sheet metal bracket. Sheet bending is defined as the straining of the metal around a straight axis. Statement of the basic laws governing deformation in sheet metal and the application of large modelling packages.

From www.youtube.com

18 types of bending operations in sheet metal Sheet metal bending Sheet Metal Bending Exercises Pdf You’ll use a combination of different flange features to create the base and utilize. Sheet bending is defined as the straining of the metal around a straight axis. In this exercise, you’ll create a sheet metal bracket. During bending operation, the metal on the inner side of the. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Cutting and. Sheet Metal Bending Exercises Pdf.

From www.youtube.com

Bending Sheet Metal Part 1 YouTube Sheet Metal Bending Exercises Pdf You’ll use a combination of different flange features to create the base and utilize. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Insert bends or “convert to sheet metal” features. Open a new sheet metal part workspace from alibre design's home. Statement of the basic laws governing deformation in sheet metal and the application of large modelling packages.. Sheet Metal Bending Exercises Pdf.

From www.minca.tw

Streamlined Sheet Metal Folding Process Sheet Metal Bending Exercises Pdf Insert bends or “convert to sheet metal” features. Cutting and forming thin sheets of metal usually performed as cold working. During bending operation, the metal on the inner side of the. Sheet bending is defined as the straining of the metal around a straight axis. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. When designing with sheet metal,. Sheet Metal Bending Exercises Pdf.

From www.engineersrule.com

sheet metal Archives Engineers Rule Sheet Metal Bending Exercises Pdf Sheet bending is defined as the straining of the metal around a straight axis. Statement of the basic laws governing deformation in sheet metal and the application of large modelling packages. During bending operation, the metal on the inner side of the. Insert bends or “convert to sheet metal” features. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick.. Sheet Metal Bending Exercises Pdf.

From www.youtube.com

Exploring Sheet Metal Bending YouTube Sheet Metal Bending Exercises Pdf Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. You’ll use a combination of different flange features to create the base and utilize. Open a new sheet metal part workspace from alibre design's home. Statement of the basic laws governing deformation in sheet metal and the application of large modelling. Sheet Metal Bending Exercises Pdf.

From jmproto.com

How to bend sheet metal? Jmproto Sheet Metal Bending Exercises Pdf Click on the sheet metal tab in the ribbon. Open a new sheet metal part workspace from alibre design's home. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. In this exercise, you’ll create a sheet metal bracket. When designing with sheet metal, it is important to think about the. Sheet Metal Bending Exercises Pdf.

From www.pinterest.com

How to Bend Sheet Metal 13 Steps (with Pictures) Sheet metal, Metal Sheet Metal Bending Exercises Pdf Open a new sheet metal part workspace from alibre design's home. During bending operation, the metal on the inner side of the. You’ll use a combination of different flange features to create the base and utilize. Click on the sheet metal tab in the ribbon. Sheet metal fabrication is the process of forming parts from a metal sheet by punching,. Sheet Metal Bending Exercises Pdf.

From munnsumeer.blogspot.com

20+ Sheet Metal Bending Calculation MunnSumeer Sheet Metal Bending Exercises Pdf Statement of the basic laws governing deformation in sheet metal and the application of large modelling packages. Sheet bending is defined as the straining of the metal around a straight axis. When designing with sheet metal, it is important to think about the best approach to model or. Open a new sheet metal part workspace from alibre design's home. Sheet. Sheet Metal Bending Exercises Pdf.

From unugtp.is

How To Bend Sheet Metal In Solidworks UNUGTP News Sheet Metal Bending Exercises Pdf You’ll use a combination of different flange features to create the base and utilize. During bending operation, the metal on the inner side of the. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Sheet bending is defined as the straining of the metal around a straight axis. Click on the sheet metal tab in the ribbon. Insert bends. Sheet Metal Bending Exercises Pdf.

From thelibraryofmanufacturing.com

Sheet Metal Bending Sheet Metal Bending Exercises Pdf Insert bends or “convert to sheet metal” features. During bending operation, the metal on the inner side of the. Cutting and forming thin sheets of metal usually performed as cold working. When designing with sheet metal, it is important to think about the best approach to model or. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Open a. Sheet Metal Bending Exercises Pdf.

From www.pinterest.com.au

Solidworks sheet metal Lofted Bend YouTube Solidworks, Sheet metal Sheet Metal Bending Exercises Pdf Cutting and forming thin sheets of metal usually performed as cold working. You’ll use a combination of different flange features to create the base and utilize. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. When designing with sheet metal, it is important to think about the best approach to model or. Insert bends or “convert to sheet metal”. Sheet Metal Bending Exercises Pdf.

From www.tek1.com.au

A detailers’ guide to sheet metal bending Tek1 Sheet Metal Bending Exercises Pdf Insert bends or “convert to sheet metal” features. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. When designing with sheet metal, it is important to think about the best approach to model or. Open a new sheet metal part workspace from alibre design's home. You’ll use. Sheet Metal Bending Exercises Pdf.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Bending Exercises Pdf Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. In this exercise, you’ll create a sheet metal bracket. Open a new sheet metal part workspace from alibre design's home. Sheet bending is defined as the straining of the metal around a straight axis. Click on the sheet metal tab in. Sheet Metal Bending Exercises Pdf.

From www.nbyichou.com

Master the Art of Bending Sheet Metal A StepbyStep Guide to Crafting Sheet Metal Bending Exercises Pdf You’ll use a combination of different flange features to create the base and utilize. Click on the sheet metal tab in the ribbon. When designing with sheet metal, it is important to think about the best approach to model or. During bending operation, the metal on the inner side of the. Cutting and forming thin sheets of metal usually performed. Sheet Metal Bending Exercises Pdf.

From www.youtube.com

SolidWorks Sheet metal Exercise 129Sketched Bend and Jog YouTube Sheet Metal Bending Exercises Pdf Sheet bending is defined as the straining of the metal around a straight axis. Cutting and forming thin sheets of metal usually performed as cold working. When designing with sheet metal, it is important to think about the best approach to model or. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping,. Sheet Metal Bending Exercises Pdf.

From metalscut4u.com

How To Bend Sheet Metal The Ultimate Guide Sheet Metal Bending Exercises Pdf Insert bends or “convert to sheet metal” features. Open a new sheet metal part workspace from alibre design's home. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. In this exercise, you’ll create a sheet metal bracket. Statement of the basic laws governing deformation in sheet metal and the application of large modelling packages. You’ll use a combination of. Sheet Metal Bending Exercises Pdf.

From robodk.com

How to Bend Metal Sheet With a Robot RoboDK blog Sheet Metal Bending Exercises Pdf Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. When designing with sheet metal, it is important to think about the best approach to model or. You’ll use a combination of different flange features to create the base and utilize. Cutting and forming thin sheets of metal usually performed as. Sheet Metal Bending Exercises Pdf.

From levstal.com

Sheet metal bending and folding services Sheet Metal Bending Exercises Pdf Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. In this exercise, you’ll create a sheet metal bracket. You’ll use a combination of different flange features to create the base and utilize. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Click on the sheet metal tab in the. Sheet Metal Bending Exercises Pdf.